Introduction

In this brief article below, we set out the basics of glove selection, with some useful guides, images and comment that we very much hope you will find interesting, helpful and informative when making that vital safety glove choice. It’s not a definitive answer to your glove selection issues, but will provide some useful insight. If you need any further information or guidance, or just have a nagging question in the back of your mind, please don’t hesitate to contact us at any time, either through the web site at www.treadstoneproducts.com/treadstone-safety/ or at our offices in Malpas, Cheshire on Tel: 01978 664667.

Standards

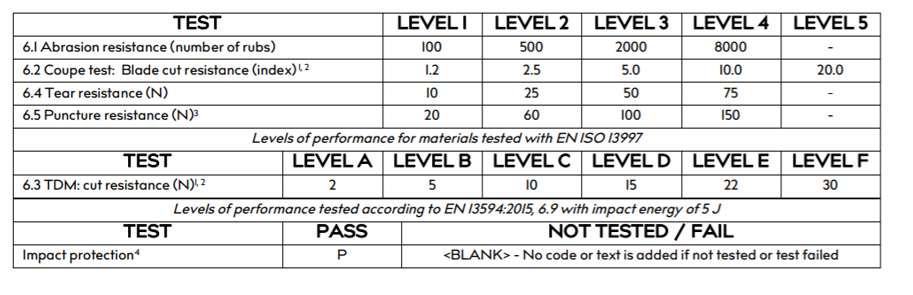

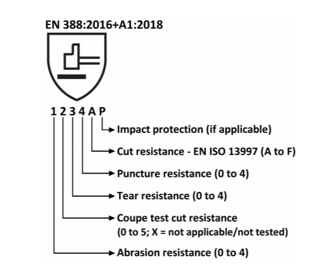

Since the initial introduction of British Standards and more recently the EU standards “cut resistant gloves” have perhaps seen the biggest change of all the glove styles. With the development of a new improved version of the EN 388 (2003) mechanical glove standards we all grew up with, (officially now titled EN 388:2016+A1:2018), cut resistance has finally come of age …and that’s great news for everybody.

The new standards ensure a more accurate method of testing and as a result, a far higher level of protection afforded by all newly approved cut resistant gloves. Our more recent familiarity with “Cut 5” being the all singing all dancing height of cut resistance performance, whilst not a distant memory, is now at last, thankfully fading fast. This is largely due to the new so called “TDM test methods” of ISO 13997. So what’s changed…?

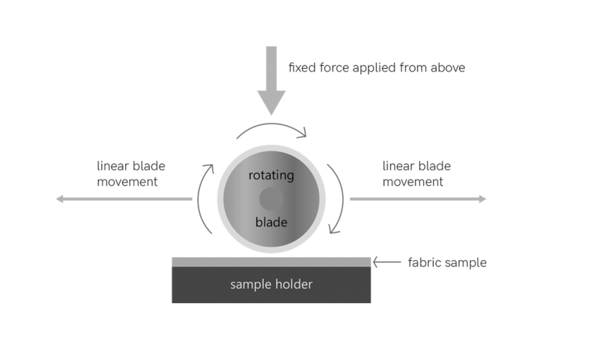

Coupe Test

Under the old standards, the coupe test was employed to measure cut resistance of a glove. This was a rotating circular blade, moving across the test fabric with a fixed force of 5 Newtons applied. Once the blade broke through the fabric and contacted the indicator below, the tests stopped and a measurement of cycles counted, against the index ( fig 1.) The problem with this, is that when the blade is blunted, the cycle count continued to the max every time.

We then see many gloves which were considered to be high cut resistance level 5, which in reality were quite poor. Imagine trying to cut through a nice steak with a butter knife..!

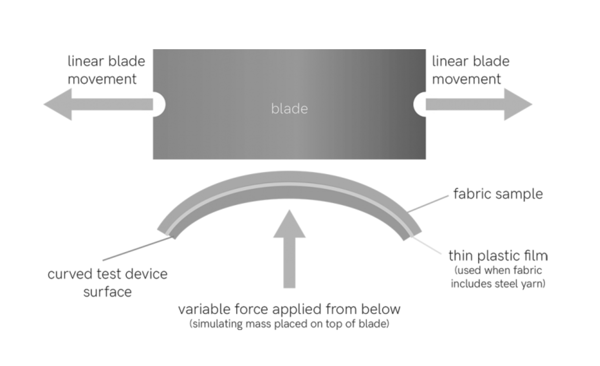

TDM Test: ISO 13997

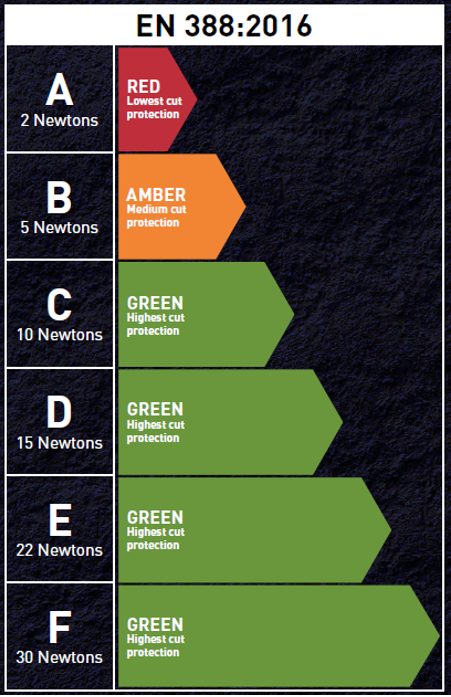

This is the game changer. So gloves which are now proven to blunt the blade on the coupe test (I.e. gloves with high glass fibre content or steel core for instance) are moved straight to the TDM test, with an X replacing the 1-5 number in the EN 388 classification and an additional letter from A-F added at the end, depending on the result (4541 becomes 4X41A-F). See table (fig 2.)

A single swipe cycle, with an increased newton force and a new blade each time ensures there’s no blunting of the blade and therefore a much more accurate result is ensured…

The fresh blade is positioned over the fabric on a curved test surface. For Level A, a force of 2 Newtons is applied and the blade pushed across the fabric. If the blade does not break through the fabric making contact with the indicator, a higher force is added for level B of 5 Newtons with a new blade and we go again… This continues until there is a breakthrough of the fabric, with a maximum force of 30 Newtons for level F, the highest cut resistance offered under the EN standards.

How can we compare old and new standards??

Regrettably, there is absolutely no correlation at all between the old EN 388 standards of cut level 1-5 and the new EN 388:2016+A1:2018 A to F standards whatsoever… We have seen several of the old cut level 5 gloves retested using the new standards and the results are quite disturbing, with some achieving just level B. Thankfully, the old style cut gloves which are lurking in every corner of the country will gradually disappear from the shelves of UK stockists, due to the expiry of their old certification, and we should finally find them all replaced with the new much improved A-F marked products….

Fig 1.

Fig 2.

It certainly all seemed a lot easier back in the late 70’s / early 80’s with just a few poorly manufactured riggers gloves, yellow criss cross, knitted wrist red PVC gloves and cotton chromes to select from, and all too often, all available “in just one size.” Back then, chemical handling was generally all about the big red PVC gauntlets and very little else…. Of course, we generally didn’t know any better at the time and “hand safety” wasn’t so much a thing back in the day. Fast forward 40+ years and the world of safety gloves is almost unrecognisable!

Driven by demands for better health and safety, the glove business is now right at the forefront of new innovative PPE technologies and the biggest changes in our industry to date…..? “Cut Resistance”.

Opposite, is a new glove selection table used by Treadstone Products “Spectrum-iD” labelled gloves. This offers the ability to choose the glove by colour coding and also easily monitor / supervise employees checking that they have green marked gloves for high risk / high cut resistance, Amber for medium risk / medium cut resistance and Red for low level cut resistance and low risk work.

Whilst this does give some guidance, it still doesn’t necessarily point you in exactly the right direction. Yes, you may decide the job is high risk, but there are also additional tools available to further help with your decision… See (fig 3.) on the next page below.

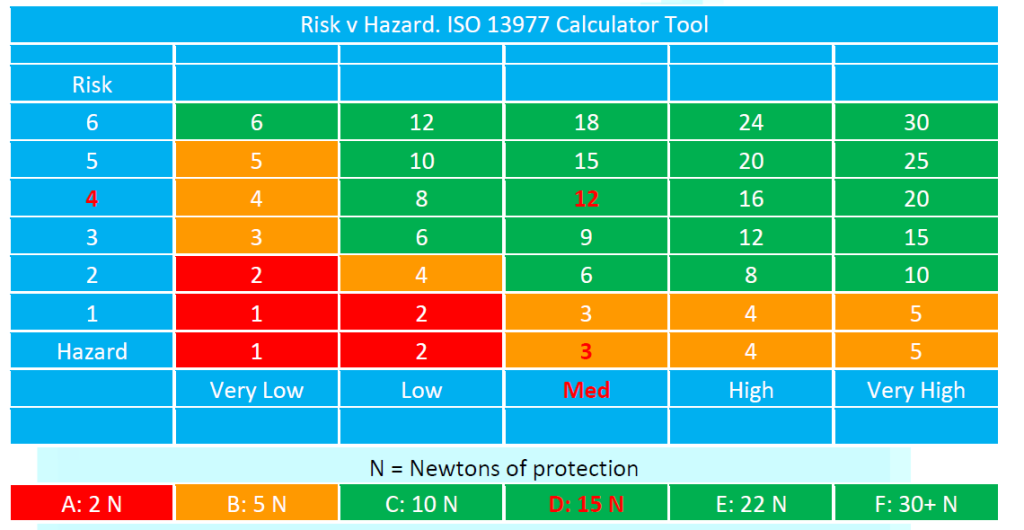

Our table here below, shows the dynamics of looking at the hazard and risks involved… Again, not 100% decisive, but a good method of getting you in the right mind-set to make that final call…

Fig 3.

his table can be used as a quick simple guide, but using a higher rated glove is always preferable, assuming good grip, dexterity, comfort, size, touch sensitivity and general performance is also acceptable. These types of gloves, should not to be used around turning / rotating machinery, such as drills, saws etc. or where there is a risk of entanglement.

Example Highlighted: Risk of cut is 4 and hazard severity is Medium. In this instance, a “Cut D” Safety Glove would perhaps be seen as the most appropriate selection. If a glove offering D or higher is acceptable in all other aspects ( some listed above ), then this could also be considered “an appropriate and informed choice”..

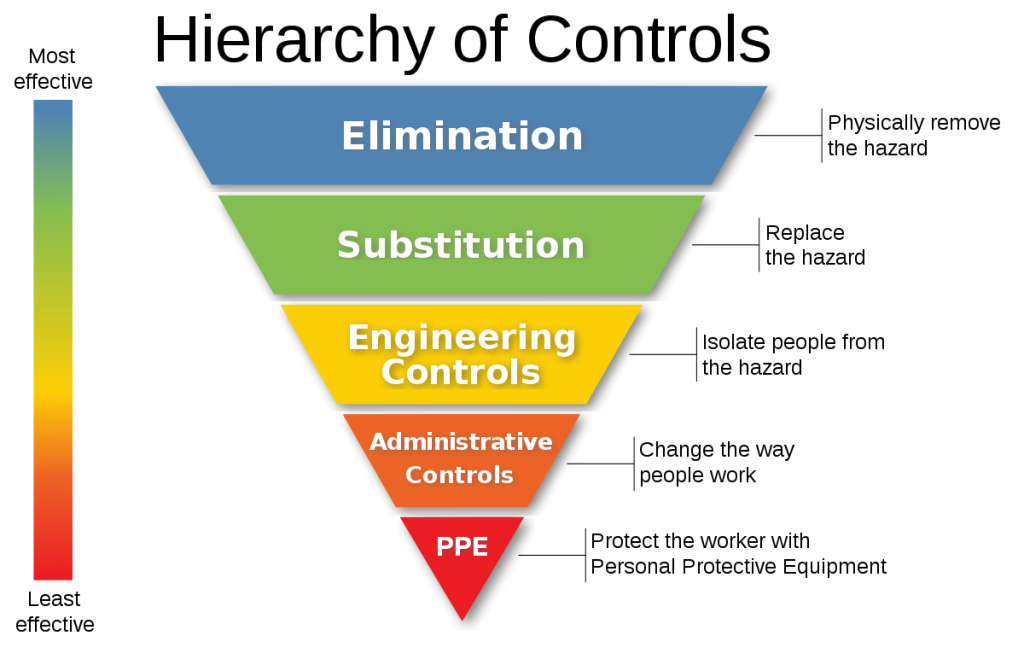

Cut resistance is, at the end of the day an indicator of just how much protection you will get when wearing a glove… Very few gloves are actually 100% resistant to cuts, but can certainly reduce the risk of injury significantly should that unfortunate incident occur. Wearing the right glove / sleeve can in many cases eliminate the risk, but PPE will always be the last line of defence… (See right) Image of the Hierarchy of Controls, commonly used in the safety industry….

Latest UK developments 2023:

UKCA. Its perhaps worth noting that, during the 2020/21/22 worldwide pandemic, we in the safety world were also consumed by the government’s decision to go ahead with Brexit. This triggered significant chaos across the UK markets, not to mention huge additional costs to business across both the manufacturing and supply chain.

From Jan 2022, all new safety products to be placed on the market in the UK were to be UKCA marked and certified, using newly appointed Approved Bodies (UK based), replacing the old European CE system, governed by Notified Bodies (now only EU based). We all thought that this was here to stay, but the drip, drip of kicking the can down the road, extending deadlines to allow companies to catch up and get on board has now unbelievably been reversed, with CE now to be accepted universally “for the foreseeable future”…

CE marked products “on the ground / already placed on the market” will remain legal to use, to buy and to sell. Nobody should feel that CE marked products are in some way inferior to the UKCA certified products or can’t be sold. The standards remain the same, with Great Britain adopting EN standards as “designated standards”. All that had changed, was literally the process of assessment, the product markings and the approved governing bodies. All CE assessed / CE marked products already placed on the GB / UK market will remain completely legal for sale and use in these markets.

All of the cut resistant product range at Treadstone Safety is now CE and UKCA certified and our new stocks coming through will all carry both markings, as we will continue to sell in both UK and EU markets. We will certainly continue to sell our existing CE marked stocks, but will provide customers with updated UKCA certification if requested and this along with all of our DoC and datasheets will be downloadable direct from our downloads section, which can be found here. With the new rules in place, there remains some uncertainty about how gloves should be marked, but as a consumer, please be assured that whether you have CE or UKCA marked product, these will be backed by testing and certification, to ensure your safety… What the future holds remains uncertain, but you can be sure, we will be right across it…

And finally……. as I said at the start, this is not a definitive solution to your cut glove selection problems. But hopefully, it has provided some useful insight into the selection process and provided enough information to make an informed choice… Still unsure?? Don’t take risks. If you need any further help or guidance, please don’t hesitate to contact us at any time. We provide glove selection / hand protection training, site surveys and problem solving for all aspects of hand protection. The journey starts right here. Contact us via the web site or via e-mail sales@treadstoneproducts.com

…and finally, “anyone can sell safety, but you wouldn’t buy safety from just anyone?”

As proud members of the BSiF (British Safety Industry Federation) and their Registered Safety Supplier Scheme, you can rely on Treadstone Safety to deliver quality, certified products and good advice. If you’re not buying from us, then please make sure you buy from somebody who is a BSiF RSSS member, for that added peace of mind…

All information correct at the time of posting Aug 2023..